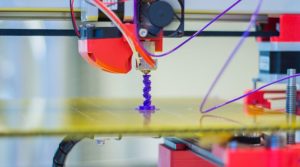

It seems as though technology is breaking barriers, disrupting nearly every industry sector and it’s possible that the steel and metals industry could be next in line. Additive manufacturing or 3-D printing isn’t a new technology; however, mechanical engineers at the Laser Zentrum Nord GmbH (LZN) research center are using the technique with metal alloys. Parts that would once take thousands of dollars to machine-tool or forge can be 3-D printed with lighter weight materials and fewer parts, and they can also be stronger.

According to the article on WSJ.com, “What 3-D Printing Can Do for Metals,” Carnegie Mellon University professor Jack Beuth is telling students to be open-minded about new production technology like 3-D printing, and how it can transform the steel and metals industry.

While still in the early stages, advanced modeling software is being used to analyze a part and evaluate the likely stresses and forces that the part will take. The software offers various shapes and structures and a design that is much lighter, and more complex, than what traditional technologies may offer – essentially redesigning a part that can be printed instead of machine-tooled.

Claus Emmelmann with the LZN research center has been focused specifically on 3-D metal printing and has noted that continuous improvements are making this technology more acceptable and available, which also means more adoptable. General Electric Co. (GE) is using metal 3-D printing to produce fuel nozzles for engines on new Boeing and Airbus planes. The one-part nozzles made by GE are 25% lighter and five times as durable. The materials and processes associated with 3-D printing could streamline production, cutting the time of manufacturing and reducing costs throughout the metals industry.

Strong Business Technology Can Support Businesses During Industry Disruption

Businesses in the steel and metals industry can also deploy stronger business technology, like RealSTEEL, to streamline operations, improving productivity and profitability. RealSTEEL offers powerful features and functions tailored for the complicated and unique processes that businesses in this industry face.

You can strengthen inventory management and production operations, gain control over finances, and produce higher quality products for customers with RealSTEEL.

There are signs that advances in 3-D printing could be disruptive to the metals industry and businesses can navigate this disruption better when armed with the right business technology. Contact The Wolcott Group for more information on improving operations with RealSTEEL.

By The Wolcott Group, providers of RealSTEEL, a ‘real world’ solution for the steel and metals industry.